The assembly and disassembly of sealing collars and U-Cups often pose a great challenge even to experienced technicians. Below you will find some tips on how to install seals with minimum effort and avoid damage to the seal and installation space. In the download section below you will find all important information as a PDF file.

When installing sealing collars and lip seals, make absolutely sure that the sealing is intact. Even minor injuries, for example to the sealing lips, can lead to failure of the entire sealing system. Cylinder and piston seals are positioned on the piston and move with it. Consequently, the dynamically stressed sealing lip is located on the outer diameter. Thus, the relevant outside diameter (in mm) of a piston/cylinder seal is usually mentioned first.

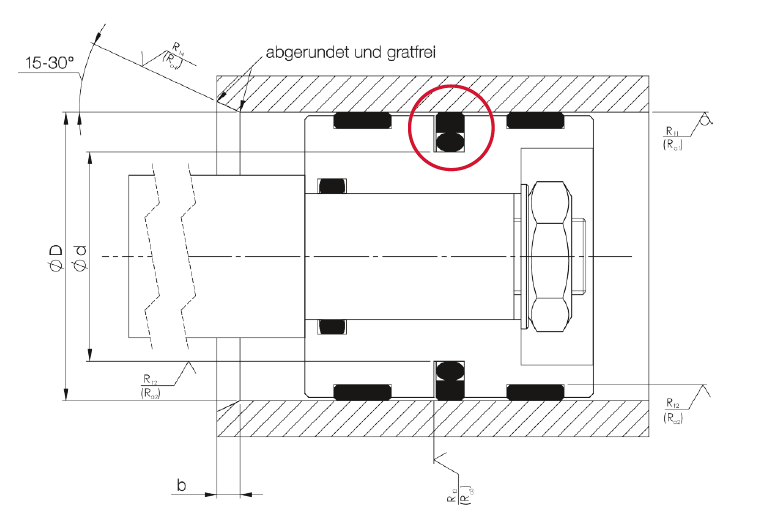

Fig.1 right: Installation situation of a piston/cylinder seal (marked red) with two guide elements